The Potential of Fiber Optic Technology in Automotive Wiring Harnesses

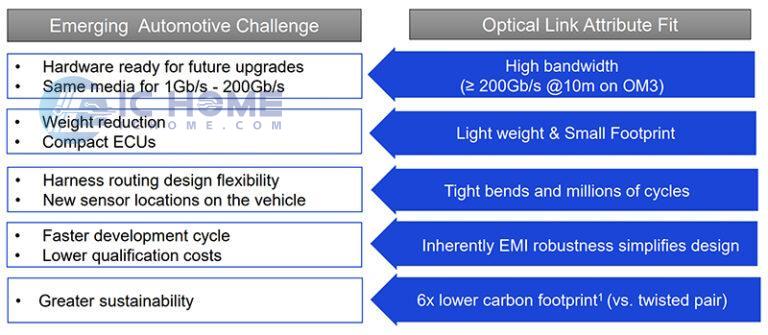

Fiber optic technology is emerging as a transformative solution in the automotive wiring harness sector. With its lightweight nature, high bandwidth capacity, and excellent electromagnetic compatibility, optical fiber addresses the growing demand for high-speed data transmission and weight reduction in modern vehicles. This article examines the application of optical fiber technology in connected, autonomous, shared, and electric vehicles (CASE) and highlights its sustainability advantages.

Optical Fiber in Modern Wiring Harnesses

In today’s vehicles, fiber optics are integrated with traditional copper wires within wiring harnesses. These fibers facilitate high-bandwidth data transfer for systems like advanced driver assistance systems (ADAS), infotainment platforms, and safety-critical controls. Their capability to handle complex video and sensor data transmission makes them ideal for linking multiple sensors to the central electronic control unit (ECU).

A notable option is OM3, a multimode fiber optic cable with a 50-micron glass core, paired with an 850-nm vertical-cavity surface-emitting laser (VCSEL). This combination offers reliable high-bandwidth performance for automotive applications.

Figure 1. Using fiber optics can bring multiple benefits to automotive wiring harnesses.

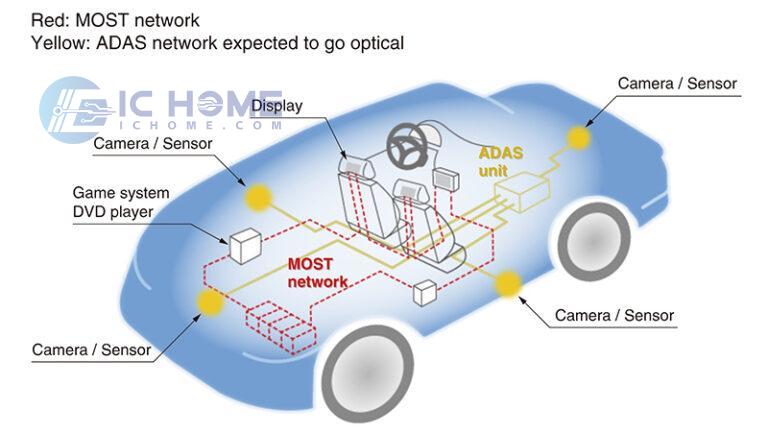

Applications in MOST and ADAS

Plastic optical fibers (POF) are widely used in Media Oriented Systems Transport (MOST) networks and ADAS. MOST variants, such as MOST25, MOST50, and MOST150, leverage POF for optical and electrical interconnections. Initially, MOST25 used a 1-mm POF core with red LED light sources.

As in-vehicle multimedia systems evolve to include high-definition video and 360-degree camera systems, optical fibers are essential for real-time image integration from multiple cameras, enabling a comprehensive view around the vehicle.

Fiber optics are increasingly being adopted for applications such as pedestrian detection systems, radar and lidar-based ADAS features, and control networks for critical systems like engines and brakes. A key application is automatic braking, where fiber’s high speed and resistance to electromagnetic interference enhance reliability.

Figure 2. MOST networks (red) are already based on fiber optic connections, while ADAS (yellow) are transitioning to fiber optics.

Supporting CASE Vehicles

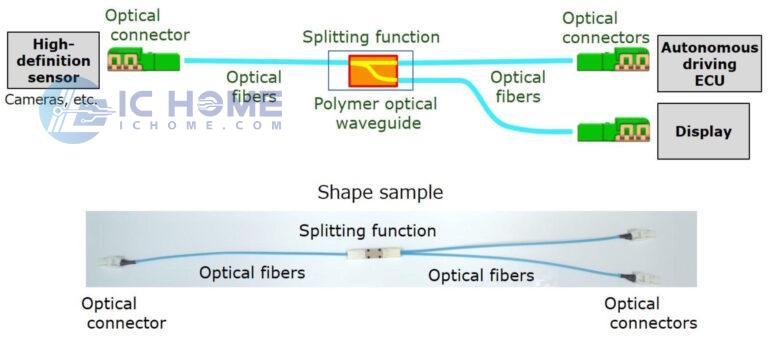

Future wiring harness designs aim to meet the demands of CASE vehicles by offering data transmission speeds exceeding 10 Gbps. This supports high-resolution sensors, including LiDAR, radar, and cameras. Polymer-based optical waveguides are being developed to passively separate optical signals without requiring additional power, enabling simultaneous data transmission to ADAS ECUs and in-cabin displays.

Figure 3. A polymer-based optical waveguide splitter function has been proposed for fiber optic wiring harnesses.

Figure 3. A polymer-based optical waveguide splitter function has been proposed for fiber optic wiring harnesses.

Sustainability Benefits

Fiber optic technology offers significant sustainability advantages. Data transmission using light pulses is more energy-efficient compared to electrical signals. Moreover, producing glass and plastic optical fibers has a lower environmental footprint compared to copper mining and cable manufacturing.

Glass fibers are made from abundant materials like sand, while plastic fibers are often crafted from recycled polymethyl methacrylate (PMMA) or polyethylene terephthalate (PET), which are common in packaging. Both glass and plastic optical fibers are recyclable, providing a greener alternative to traditional wiring materials.

Fiber optic technology not only meets the functional demands of modern vehicles but also aligns with sustainability goals, making it an ideal solution for the future of automotive wiring harnesses.

More products about optical fiber, please visit ICHOME.