The Importance of Choosing A Supplier's Reputation

In the procurement process of electronic components, it is crucial to choose a reliable supplier. Long-term and stable suppliers can not only guarantee product quality, but also effectively reduce supply chain risks. This article will explore in depth how the reputation of component suppliers affect procurement decisions to help you make a more informed choice.

1. Supplier Reputation: Guarantee of Quality and Stability

When choosing a component supplier, reputation is a key factor that cannot be ignored. The reputation of a supplier is usually closely related to its past service record, customer feedback, and industry reputation. Suppliers with long-term operations and good reputation can often ensure the following aspects:

Stable product quality: Time-tested suppliers usually have stable quality control processes to avoid product quality fluctuations, which is crucial for electronic manufacturing companies. Especially for components that require high precision and high reliability, stable quality can effectively reduce the rework rate and product failure rate in the production process.

Efficient after-sales service: Suppliers with good reputation usually provide strong after-sales support, including technical consultation, product replacement, quality problem follow-up and other services, to ensure that customers can get timely solutions when they encounter problems after procurement.

2. Long-term Stable Suppliers and Lower Risks

Choosing long-term suppliers can bring many advantages, especially in component procurement, these advantages are particularly obvious:

Predictability of delivery cycle: Establishing a stable cooperative relationship with a long-term supplier can ensure on-time delivery and avoid production delays caused by untimely supply. For large-scale production companies, the ability to deliver on time is the key to the stability of their supply chain.

Flexible supply chain management: Long-term cooperative relationships mean that suppliers can better understand customer needs, predict market changes in advance, and provide customized solutions. Suppliers can also provide more flexible inventory management and regular deployment according to customer needs to reduce the risk of supply interruptions.

Reduce quality control costs: By cooperating with stable suppliers, companies can reduce frequent testing and review of product quality and reduce additional costs and risks caused by unqualified products.

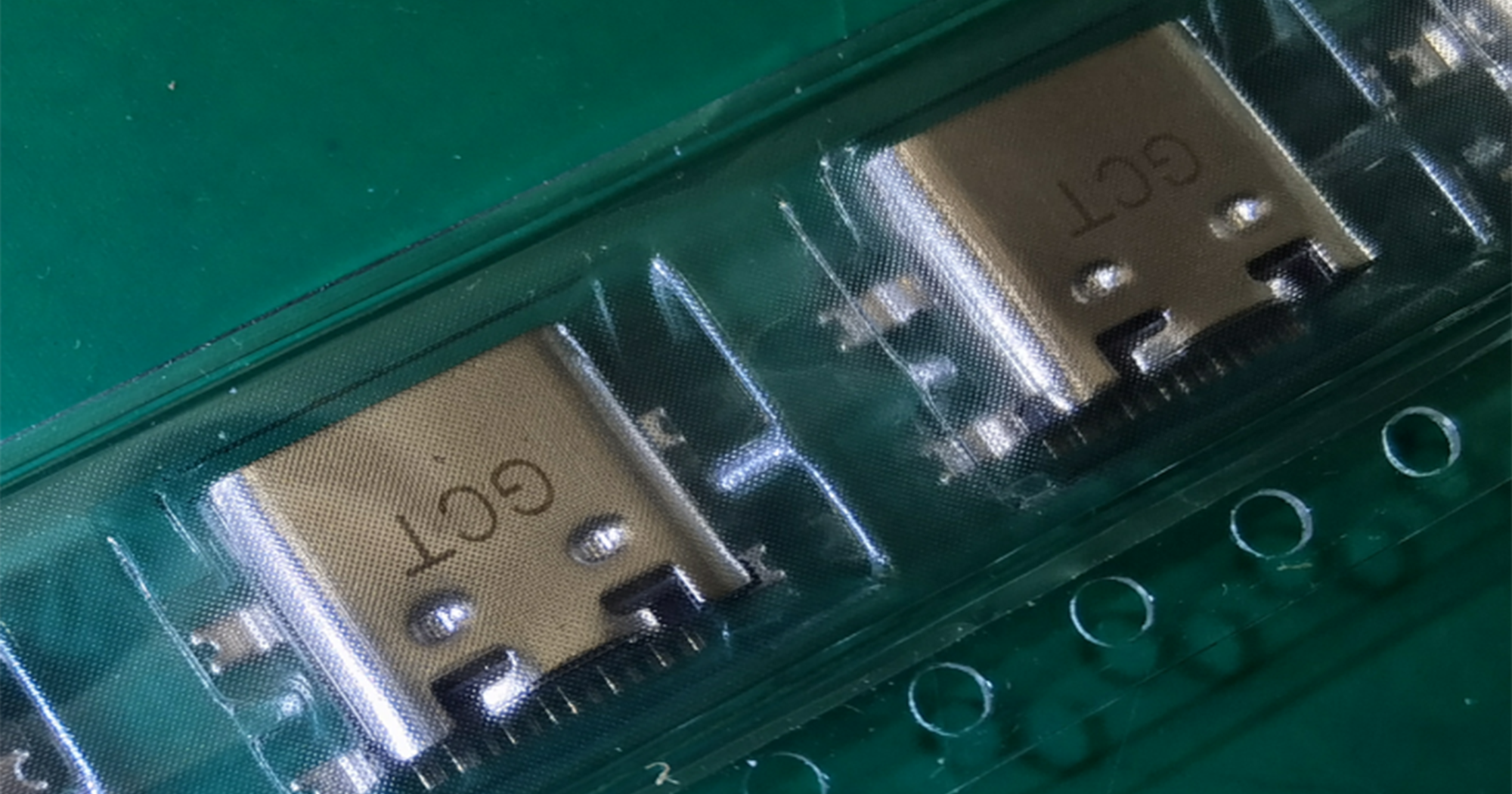

3. Supplier History: The Key to Ensuring Procurement Quality

The supplier's historical record is also one of the important factors in evaluating its reliability. Suppliers with a long history usually have the following advantages:

Technology accumulation: Long-term industry accumulation enables suppliers to continuously optimize technological innovation and production processes, thereby providing higher quality and more competitive products. Especially in the field of complex electronic components, technology accumulation is crucial for product stability and performance optimization.

Experienced quality control system: Suppliers have accumulated a complete quality management system in the long-term operation process, which can ensure strict control in every link from design, production, inspection to shipment to prevent unqualified components from entering the market.

Reliable cooperation history: Suppliers with a long history often have long-term cooperation experience with large enterprises or internationally renowned brands. This stable cooperation relationship is also a reflection of their credibility. Customers can understand the actual performance and market reputation of suppliers through their past partners.

4. Reduce Procurement Risks: Choose a Trustworthy Supplier

Choosing a supplier with credibility and history can effectively reduce potential risks in the procurement process:

Reduce the risk of unqualified products: High-quality suppliers will have strict quality control measures to ensure that the components provided meet the standards and reduce the risk of unqualified products entering the production line.

Risk of supply chain disruption: Cooperating with reputable suppliers can effectively avoid supply chain disruptions caused by poor supplier management and insufficient supply of raw materials. Stable suppliers can usually maintain a relatively stable supply capacity during peak production.

Technology and compliance risks: Excellent suppliers will keep up with industry technology and market changes to ensure that their products meet the latest technical standards and compliance requirements, helping customers avoid risks caused by product non-compliance with regulations.

5. Conclusion: Work Hand in Hand With Reliable Suppliers

In the procurement of electronic components, choosing a reputable and long-standing supplier can effectively reduce procurement risks, improve product quality, and ensure the stability of the production process. As a corporate decision maker, you should consider multiple factors such as its reputation, history, technical accumulation, and quality control capabilities when selecting suppliers to make scientific decisions.

When choosing a component supplier, you should not only pay attention to the current cost and price, but also consider long-term cooperative relationships and the stability of the supply chain. Only by working with reliable suppliers can we achieve sustained growth and success in a complex and changing market environment.

As a trusted electronic component distributor, ICHOME has always been committed to providing customers with high-quality products and professional technical support with many years of industry experience and stable supply chain management. Choosing ICHOME makes your procurement simpler, more efficient, and more secure.