Trends in the Industrial Camera Market and Oscillator Applications

Industrial cameras are specialized devices used in industrial automation and machine vision fields. They efficiently capture images of target objects and integrate with automation systems for image processing and analysis. As Industry 4.0 and smart manufacturing advance, the demand for industrial cameras has grown rapidly, particularly in quality inspection, production line monitoring, automation control, and machine vision applications.

The primary application sectors for industrial cameras include manufacturing, electronics, pharmaceuticals, automotive, and logistics. With the increasing automation in these industries, the market for industrial cameras has seen rapid growth.

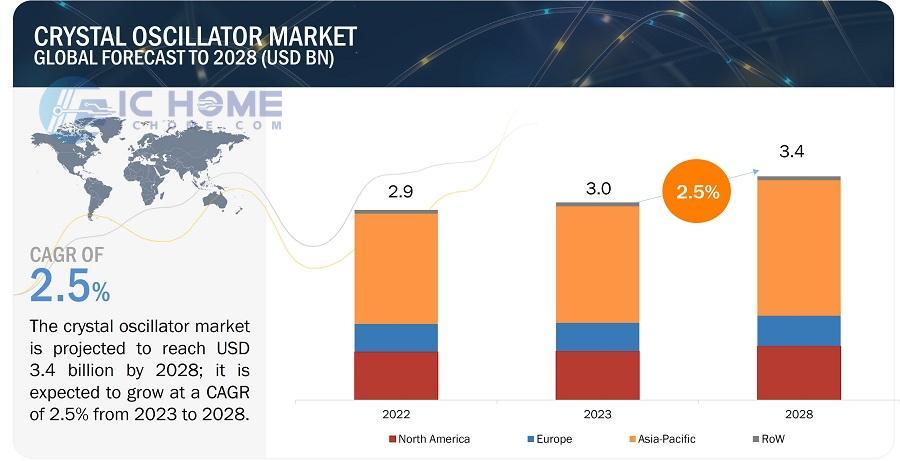

Market research indicates that the industrial camera market has maintained robust growth, especially in the Asia-Pacific region, where the demand is especially strong. By 2025, the global industrial camera market is expected to reach billions of dollars. This growth can be attributed to several major trends:

Smart Manufacturing and Industry 4.0

The core of Industry 4.0 revolves around smart manufacturing and automation. Machine vision, a critical technology, has significantly boosted the demand for industrial cameras.

Integration of Artificial Intelligence and Big Data

With the advancement of AI and big data technologies, industrial cameras have evolved from simply capturing images to incorporating deep learning, edge computing, and real-time data analysis for more complex decision-making.

High Resolution and Speed

As industries demand higher precision and efficiency, the technology behind industrial cameras continues to upgrade. Cameras with high resolutions (such as 8K and beyond) and fast imaging speeds are expected to dominate the market.

Diverse Interfaces and Communication Protocols

With the rise of the Industrial Internet of Things (IIoT), industrial cameras that support multiple communication protocols (e.g., EtherCAT, Profinet) can seamlessly integrate into automation systems, enhancing data flow and system collaboration.

In these applications, industrial cameras require highly accurate and precise clocking devices to synchronize the various components, ensuring stable signal processing.

Oscillator Applications in Industrial Cameras

In the various modules of industrial cameras, crystal oscillators (crystals) provide precise clock signals, ensuring the synchronization of system components and accurate signal processing. Different modules have varying requirements for oscillator parameters, including frequency, precision, and temperature stability. Critical components such as communication, image processing, and video output modules require specific frequency selection based on the application.

Common Frequencies Used in Industrial Cameras:

32.768KHz, 24MHz, 25MHz, 27MHz, 40MHz, 100MHz, 125MHz, 156.25MHz

32.768KHz Resonator: The standard industrial camera design currently uses a 32.768KHz resonator packaged in a 3.2*1.5 form factor.

MHz Resonators: For industrial cameras, MHz resonators are typically used in 3225/2520 sizes, and some sensor applications require smaller oscillators.

CMOS Oscillators: Industrial cameras require oscillators with high precision and stability. Some modules may require oscillators with specific frequencies, which can be customized using pre-programmed oscillators.

Differential Oscillators: For gigabit Ethernet industrial cameras, higher frequency oscillators like 156.25MHz are commonly used, with stringent jitter requirements to ensure signal integrity.