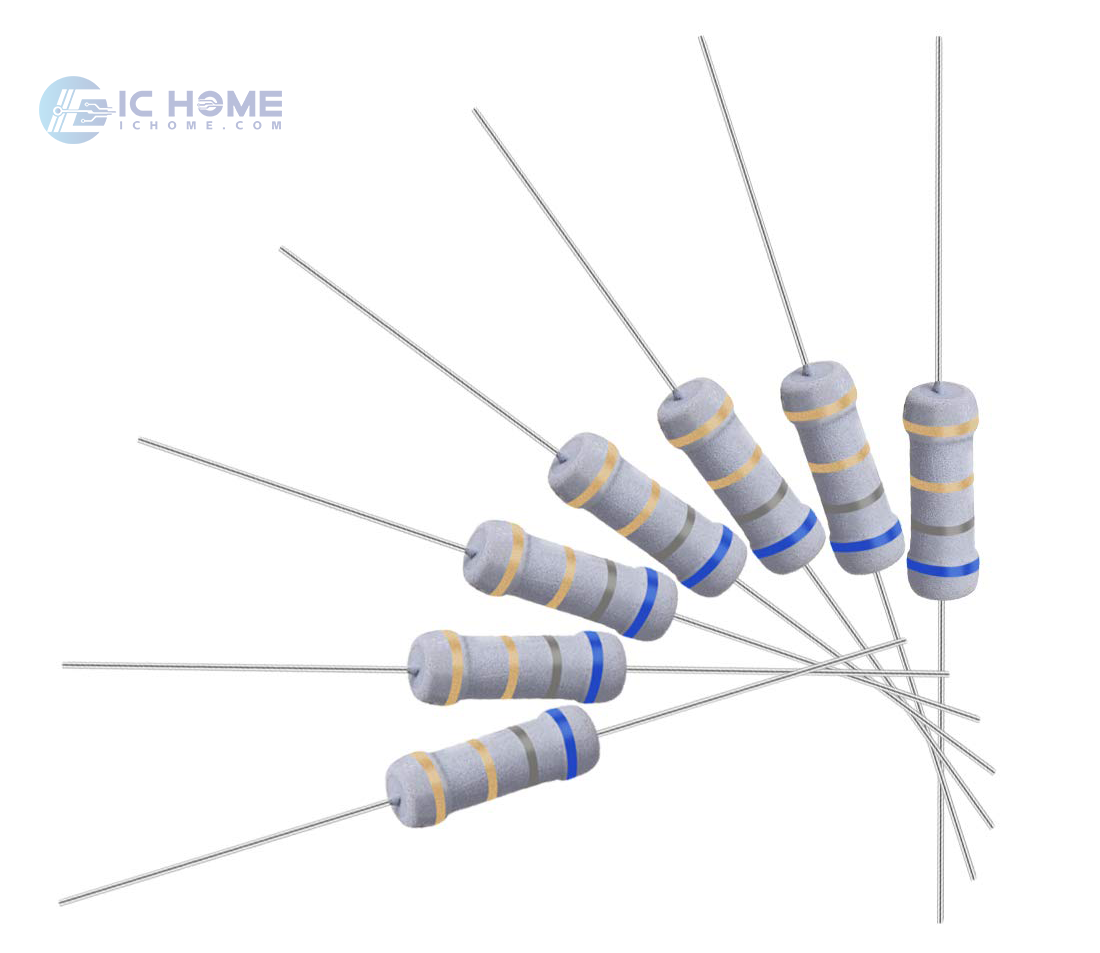

What Does Tolerance ±5%, 10%, 15% in Resistors Mean?

When selecting resistors for an electronic circuit, tolerance is a key specification that indicates the permissible variation between the resistor's actual resistance and its nominal (stated) value. Understanding this parameter is crucial for procurement professionals and engineers, as it directly impacts circuit performance. This article explains resistor tolerances, common tolerance values, and how to choose the right one for your application.

What is Resistor Tolerance?

Resistor tolerance is expressed as a percentage, such as ±5%, ±10%, or ±15%.

Definition: Tolerance specifies how much the actual resistance value can deviate from the nominal value. For example, a 1kΩ resistor with ±5% tolerance could have a resistance between 950Ω and 1050Ω.

Significance: The smaller the percentage, the closer the resistor's actual value is to the stated value, which means better accuracy and performance.

Tolerance is crucial for precision circuits, such as medical devices or instrumentation, where small variations can significantly impact functionality.

Common Resistor Tolerances

±5% (General Purpose):

Found in carbon film resistors, these are suitable for cost-effective applications where high precision is not critical, such as consumer electronics or basic circuits.

Example: LED circuits or power supplies.

±10% and ±15% (Low Accuracy):

Common in older resistor technologies like carbon composition. These are rarely used today due to advancements in manufacturing processes.

Suitable for non-critical, high-variation environments.

±1% or Lower (Precision Resistors):

Found in metal film and wire-wound resistors. These are used in high-precision applications, such as measurement instruments or signal processing.

Example: Oscilloscopes or medical devices.

Why Do Different Tolerances Exist?

Different tolerances cater to varying application needs and budgets.

Cost vs. Accuracy: Lower tolerances (e.g., ±1%) are more expensive due to tighter manufacturing processes. Higher tolerances (e.g., ±5% or ±10%) are more affordable for general-purpose applications.

Application Requirements: Precision circuits demand low tolerance, while basic circuits (e.g., simple LEDs or pull-up resistors) can tolerate higher variations.

Environmental Factors: Circuits in extreme environments (e.g., high heat or humidity) may require tighter tolerances to ensure consistent performance.

How to Choose the Right Tolerance?

Consider the following when selecting a resistor tolerance:

Application Sensitivity: For critical circuits like audio amplifiers or temperature sensors, opt for ±1% or tighter tolerances.

Budget: General-purpose circuits, such as DIY electronics or power regulators, can use ±5% resistors to save costs.

Manufacturer Specs: Leading manufacturers like Vishay and Yageo offer resistors with various tolerances to suit specific needs.

Conclusion

Understanding resistor tolerance is essential for making informed decisions when designing or sourcing electronic components. Whether you need precision for sensitive devices or cost-efficiency for simple circuits, tolerance determines the balance between performance and budget.

By recognizing the importance of resistor tolerances and their applications, you can optimize your designs for accuracy, reliability, and efficiency. Next time you see ±5% or ±1% on a resistor, you’ll know exactly what it means and why it matters.

For more information or to request a quote, please feel free to send us an RFQ.

Some Model Numbers