Chip Function Test: Protection of Electronic Products

With the rapid development of integrated circuit technology, the chip's functional complexity and integration is increasing, to ensure the quality of the chip factory one of the key steps is to carry out detailed and comprehensive functional testing. Chip function test is to verify whether the chip design meets the predetermined specifications, whether the performance is up to standard, and whether it can work stably in the expected environment of the core link. The following are the main test categories and their contents included in the chip function test:

1. Logic function test:

Functional test: Through inputting preset data patterns to the chip and checking the output results, it verifies whether each logic unit within the chip performs arithmetic and processing tasks correctly according to the design requirements.

Timing test: Detect whether the timing relationship between the signal paths inside the chip meets the design specifications, including parameters such as setup time and hold time.

Performance test: Evaluate the chip's operating speed, response time and data throughput to confirm its performance under high-speed operation.

Stability test: Observe the behavior of the chip under long-time working conditions to ensure its stability under various load conditions.

2. Power supply and power management test:

Power consumption test: Measure the static power consumption, dynamic power consumption and total power consumption of the chip in different operating modes to check whether there are problems such as leakage, short-circuit or substandard power efficiency.

Power integrity test: Ensure that the chip can still work normally under power fluctuation, and assess the impact of the power network on the chip's performance.

3. Signal integrity and electrical performance test:

Signal integrity test: Check all input/output interface signals of the chip, including but not limited to clock, data and control signals, test their amplitude, rise/fall time, noise tolerance and anti-interference capability.

DC parameter test: Determine the threshold voltage, turn-on current, saturation current and other DC characteristic parameters of the chip.

AC parameter test: involves the measurement of frequency response, gain, noise figure and other related electrical performance indexes.

High-speed digital signal performance test: verify the signal quality and BER of the chip during high-speed data transmission.

4. Environmental tolerance and reliability test:

Temperature cycling test: Place the chip in a high or low temperature environment to verify its performance consistency and reliability under extreme temperature changes.

Humidity sensitivity test: Evaluate the performance changes and potential corrosion risk of the chip under different humidity conditions.

High voltage pulse test: Simulates the abnormal electrical conditions that the chip may encounter by applying high voltage pulses to test its ability to withstand over-voltage and the effectiveness of the protection mechanism.

Reliability test: Including pin wire ball/solder joint reliability, pin wire elasticity reliability, and resistance to mechanical stress test, etc., to verify the long-term durability of the package structure and connecting parts.

5. Other specific tests:

Memory test: For chips with integrated memory, conduct integrity and error rate tests for read and write operations.

Clock frequency test: Verify that the frequency response of the chip's internal and external clock sources meets the design requirements.

Leakage current and current limit test: Ensure that the leakage current of the chip in the no-signal state is in the acceptable range, and will not exceed the safe current limit under maximum load conditions.

Chip function test is a very important process, like a comprehensive “physical examination” for the chip. Chip function test is an indispensable part of the chip manufacturing process, which provides a guarantee for the reliable operation of electronic products. As semiconductor technology becomes more and more advanced, the inspection standards for chips will also become higher and higher.

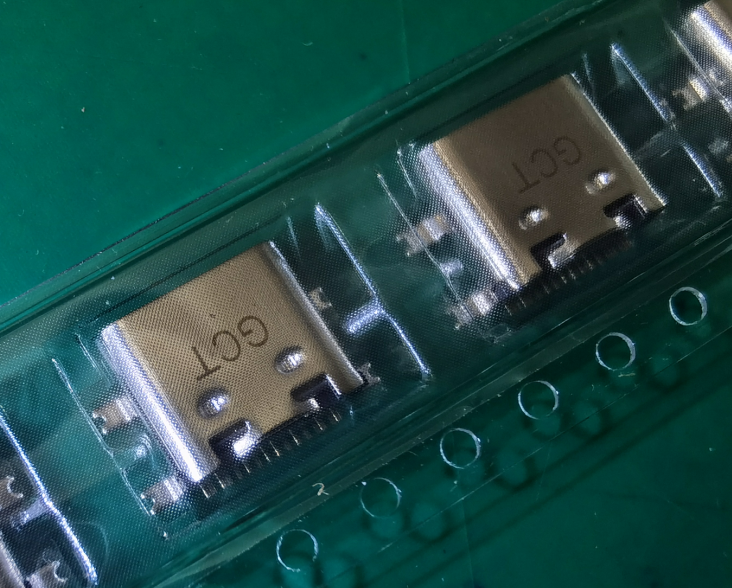

If you have a need for chips, you can contact ICHOME, while we will provide relevant inspections and issue inspection reports.