What to Consider When Choosing a Header Connector for Your Project

Header connectors with male pins are essential in electronic assemblies, providing a reliable interface between PCBs (printed circuit boards) and other components. For procurement professionals, engineers, and electronics enthusiasts, selecting the right header connector is critical to ensure performance, durability, and compatibility. Here's a guide to help you make an informed decision.

Pitch: Precision in Spacing Matters

The pitch of a header connector refers to the distance between the centers of adjacent pins, typically measured in millimeters (mm). Common pitch sizes include 2.54mm (0.1 inches), 2.0mm, and 1.27mm. Choosing the correct pitch depends on the following factors:

Space Constraints: Smaller pitch connectors (e.g., 1.27mm) save board space, making them ideal for compact designs like wearable devices or IoT products.

Ease of Assembly: Larger pitch connectors, such as 2.54mm, are easier to handle and solder, making them suitable for prototypes or projects requiring manual assembly.

Signal Integrity: Smaller pitches may lead to crosstalk issues in high-frequency applications. Consider signal requirements when determining pitch.

Selecting the appropriate pitch ensures a balance between space optimization and functionality, tailored to your project’s needs.

Current Rating: Matching Power Demands

The current rating of a header connector defines how much current each pin can safely carry without overheating. When choosing a connector, keep the following in mind:

Application Power Requirements: High-power applications, such as motor drives, demand connectors with higher current ratings. For low-power applications, such as sensors, standard ratings suffice.

Operating Temperature: Ensure the connector can handle the heat generated by the current without compromising performance or lifespan.

Pin Count and Distribution: The total current load is distributed across the pins. A higher pin count may reduce the current burden on each pin, enhancing reliability.

Always select a connector with a current rating higher than your application’s maximum current to maintain a safe operating margin.

Material: A Key to Longevity and Performance

Materials used in header connectors significantly affect their performance, durability, and cost. Key material considerations include:

Pin Material and Coating: Gold-plated pins offer superior conductivity and corrosion resistance, ideal for high-reliability applications. Tin-plated pins are a cost-effective alternative for general-purpose use.

Housing Material: Common materials like polyamide or polyester ensure robust insulation and mechanical stability. Flame-retardant housings may be necessary for safety-critical applications.

Temperature Tolerance: Materials should withstand the operating environment’s temperature range, especially in industrial or automotive settings.

By evaluating materials, you can ensure that the connector meets your application’s mechanical and environmental demands.

Additional Features: Tailoring for Specific Needs

Modern header connectors offer various features to address specific requirements. Some key considerations include:

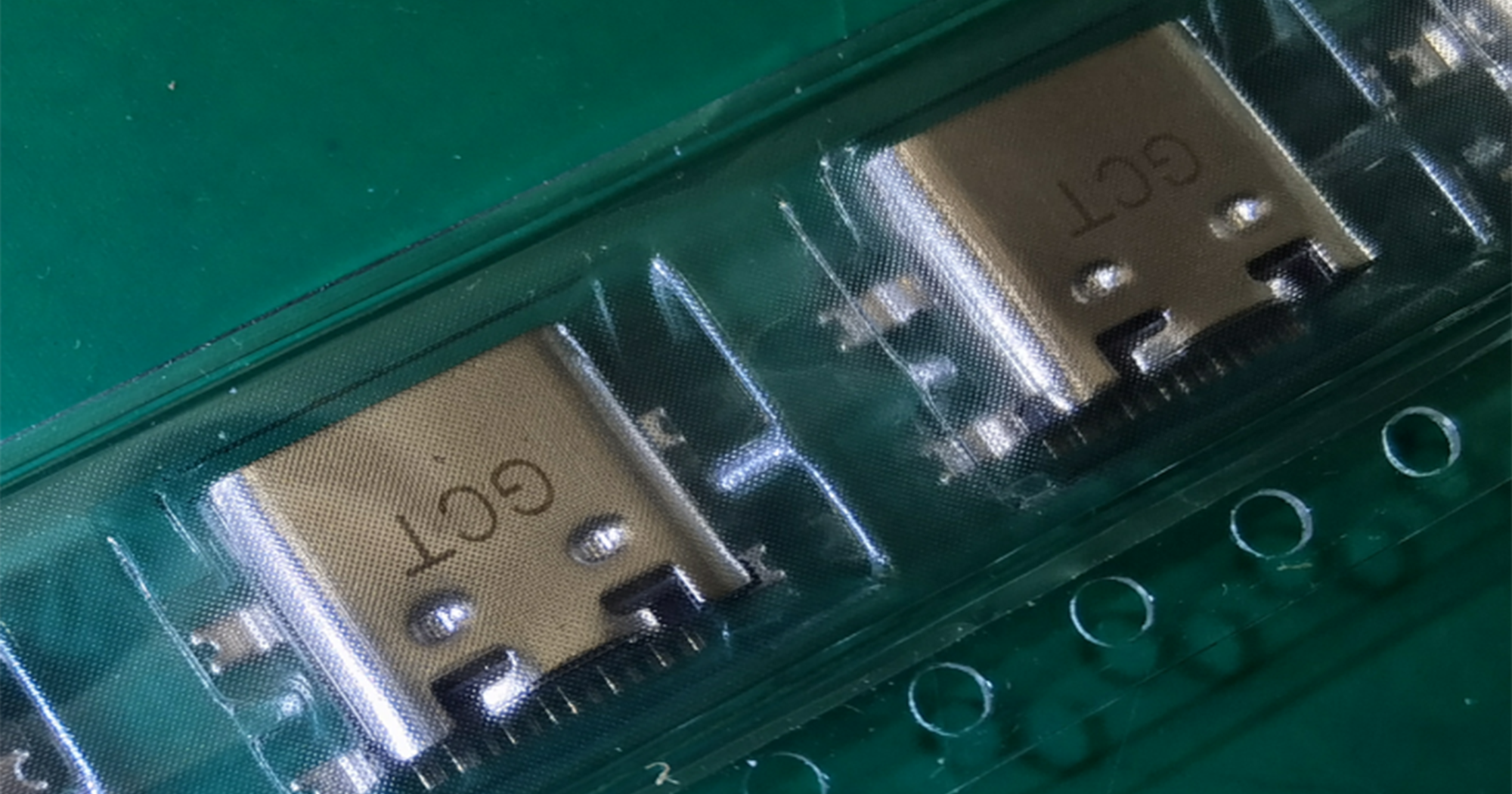

Mounting Style: Choose between through-hole or surface-mount technology (SMT) connectors based on your assembly process.

Locking Mechanisms: Locking tabs or latches enhance connection stability, critical for applications subject to vibration.

Customization: Consider connectors that offer angled pins, varying pin lengths, or specific configurations to suit your design.

Environmental Protection: For outdoor or harsh environments, opt for connectors with weatherproofing features such as sealing or IP-rated housings.

These features add versatility and adaptability, ensuring your connector performs optimally in its intended application.

Summary: Finding the Right Balance

Choosing the right header connector involves more than just fitting pins into sockets. By considering factors such as pitch, current rating, material, and additional features, you can optimize your design for functionality, reliability, and cost-efficiency. For procurement professionals and engineers, understanding these aspects can streamline the selection process, ensuring your project’s success.

Whether you’re working on a consumer gadget or an industrial control system, taking the time to evaluate your connector needs will pay dividends in the form of better performance and fewer issues down the line.

For more information or to request a quote, please feel free to send us an RFQ.

Some Model Numbers