Solving SiC MOSFET Packaging Complexities

The increasing popularity of wide bandgap devices requires innovative advances in packaging technology to take full advantage of WBG semiconductors.

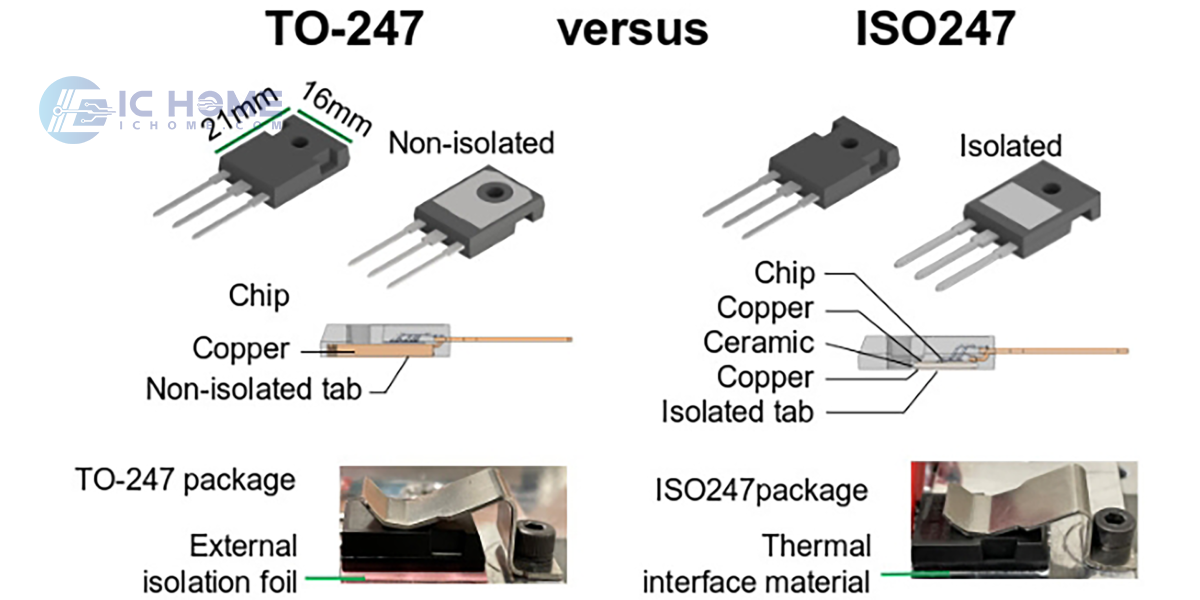

Traditional discrete SiC MOSFETs rely on external thermally conductive electrical isolation materials to isolate them from the heat sink. Not only does this increase the junction-to-heatsink thermal resistance, it also complicates thermal management and creates obstacles for automated and manual assembly processes. Additionally, poor thermal conductivity reduces power and current handling capabilities, significantly limiting the optimal utilization of SiC chips.

ISO247 – High Performance Ceramic Discrete Isolation Package

Littelfuse's ISO247 package uses high-performance silicon nitride (Si3N4) ceramic to solve these challenges, improve SiC chip utilization and enhance SiC MOSFET-based applications. The ISO247 is part of the ISOPLUS family of internally isolated discrete power semiconductor device packages using a direct copper bonding (DCB) substrate and aluminum oxide (Al2O3) ceramic, first introduced in 2003 by IXYS Semiconductor (now part of Littelfuse). ISO247 complies with JEDEC TO-247AD standard, ensuring pin compatibility with standard TO-247 packages. ISO247 covers a wide range of semiconductor technologies, including Si/SiC MOSFETs, IGBTs and diodes, with voltage levels ranging from 70 V to 1600 V. The ISO247 package utilizes advanced high-performance silicon nitride ceramics and is tailored to meet the demanding requirements of SiC MOSFET-based applications. It has the following main advantages compared to standard TO-247:

-High-performance ceramic-based active metal braze (AMB) substrate provides inherent isolation, higher thermal conductivity and lower junction-to-heatsink thermal resistance

-Isolation voltage rating is 2.5 kV AC for 1 minute or 3 kV AC for 1 second

-Higher temperature and power cycle (in seconds) withstand capability due to matching coefficients of thermal expansion (CTE) of the SiC chip and AMB substrate

-Increase power density and simplify thermal management

-Reduced electromechanical interference due to smaller stray capacitance between chip and heat sink

Although the ISO247 and TO247 packages have the same external dimensions and pin configuration, their internal structure and mounting methods are significantly different, as shown in following Figure. While TO-247 devices require external isolation when mounted to a heat sink, ISO247 devices only use thermal interface material when mounted to a heat sink. Note: The thermal interface material does not provide electrical isolation; its function is only to improve thermal conductivity.

Thermal Performance Comparison: ISO247 and TO-247

The standard TO-247 package has a conductive mounting pad, usually at drain potential. For safety reasons and the desire to mount multiple discrete devices on the same heat sink frame, it is often desirable to electrically isolate the device mounting tabs from the heat sink. To this end, the use of an external thermally conductive electrical isolation foil between the semiconductor package and the heat sink has become a widely adopted approach in the industry. Nonetheless, there are significant drawbacks to using external isolation. Increased thermal resistance, reduced power and current handling capabilities, complex thermal management, and high assembly effort are all direct or indirect consequences of external isolation strategies. The above disadvantages, especially reduced power handling capabilities, become unacceptable, especially when using wide bandgap (WBG) semiconductors such as SiC MOSFETs.

ISO247 solutions also offer considerable cost-saving opportunities:

-Direct cost savings are attributed to enhanced current and power handling capabilities, increased power density, PCB area savings, and reduced SiC chip costs

-Saves overhead costs by reducing potential warranty claims by eliminating barrier foil

Unique packaging for WBG devices

The growing popularity of WBG devices requires continued innovation in packaging technology to take full advantage of WBG semiconductors. ISO247 is a unique isolation package designed to meet the stringent requirements of SiC-based applications while being compatible with the standard TO-247 footprint. In short, due to the improved thermal resistance RthJHC and power dissipation PDJH of ISO247 packages using high-performance ceramics, engineers can select a higher R DS(on) chip for a given application power rating. This provides significant cost-saving opportunities at a system level. Additionally, adopting ISO247 in power electronics applications reduces installation effort, saves space, lowers overall thermal resistance and increases power density while simplifying thermal design.