Optimizing Cooling Fans in Electronics Practical Insights

Cooling fans are essential in electronics, maintaining optimal temperatures to prevent overheating and ensure reliability. As electronics become more compact yet more powerful, choosing the right cooling fan is vital for performance and longevity. This guide will explore top cooling fan models, their applications, and provide insights tailored to procurement professionals, engineers, and others in the electronics industry.

Cooling Fan Manufacturers: Leading the Way in Innovation

When selecting cooling fans, manufacturers play a crucial role in determining the quality, reliability, and technological advancements embedded in these components. Here are a few top manufacturers known for their innovation and quality:

Delta Electronics is a leader in power and thermal management solutions, providing high-quality cooling fans used across industries. Their models feature advanced designs, emphasizing energy efficiency and durability. Delta’s cooling fans, available in various sizes and configurations, cater to the stringent requirements of medical, industrial, and data center applications.

Known for precision and innovation, NMB Technologies offers cooling fans designed to meet the demands of various applications. They provide a range of models with advanced noise reduction, vibration minimization, and robust design, ideal for automotive and telecommunications.

Sanyo Denki focuses on high-performance fans that handle extreme environments. Their cooling fans are renowned for their long lifespan and high-temperature tolerance, making them a trusted choice in industrial and outdoor settings.

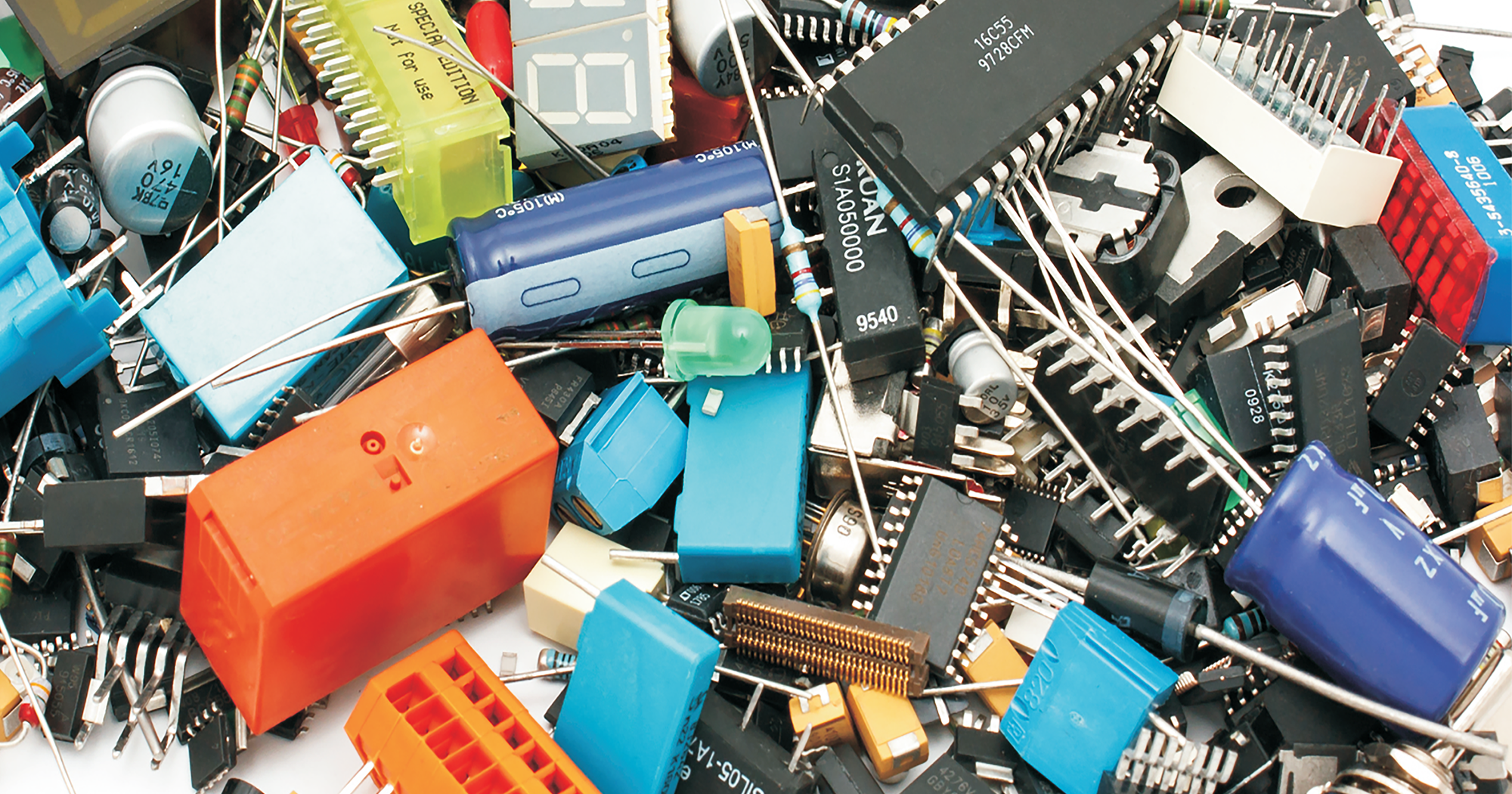

Core Components and Parts of Cooling Fans

The design of cooling fans includes several critical parts that influence performance:

Rotor and Blades: The rotor, fitted with blades, is the central moving component that circulates air. The shape, angle, and number of blades determine airflow capacity and noise levels.

Bearing System: Bearings influence fan lifespan and noise levels. Options like ball bearings and sleeve bearings offer different benefits, with ball bearings being more durable and better suited for high-temperature environments.

Frame and Housing: Frames, typically made from plastic, aluminum, or steel, provide structural support and affect airflow dynamics. Aluminum frames are preferred for high-durability applications, while plastic frames reduce weight and are common in consumer electronics.

Motor: Motors are crucial for powering the fan. Brushless DC motors are popular due to their efficiency, low maintenance, and minimal noise production.

Applications of Cooling Fans in Electronics

Cooling fans have applications across various electronics sectors, each with specific requirements:

Data Centers and Servers

Servers operate continuously, generating considerable heat. Cooling fans designed for data centers emphasize high airflow and energy efficiency. Variable speed fans are common, adjusting RPMs based on temperature, reducing energy consumption during low activity periods.

Medical Devices

Medical electronics, like imaging systems and diagnostic machines, demand precision and reliability. Cooling fans in these applications require silent operation and strict adherence to temperature control. Models designed for medical use prioritize low noise and high precision, ensuring both patient comfort and device functionality.

Automotive Electronics

Automotive electronics, including engine control units (ECUs) and infotainment systems, rely on cooling fans to maintain stability in varying temperatures. Fans used in automotive applications are built for durability, often utilizing ball bearings for extended lifespan, and must withstand high-vibration environments.

Consumer Electronics

For consumer electronics like gaming consoles, laptops, and smartphones, cooling fans prioritize low noise and compact design. These fans ensure comfortable device temperatures during extended use without disturbing the user. Miniature models and brushless DC motors are often employed here to meet both compactness and efficiency needs.

Key Specifications: Understanding Package and Case

Cooling fans come in various packages and cases that affect compatibility and functionality:

Package

The package defines the fan's physical dimensions and includes critical specifications like diameter, depth, and mounting options. Compact fan packages are essential for small devices, whereas larger packages cater to high-power applications that demand substantial airflow.

Case Material

The case material influences durability and thermal resistance. Aluminum cases are lightweight and offer excellent heat dissipation, making them ideal for high-performance applications. Plastic cases, on the other hand, are common in cost-sensitive and lightweight applications, balancing performance and affordability.

Choosing the Right Cooling Fan for Your Needs

When selecting a cooling fan, several factors should guide the decision:

1. Airflow Requirements (CFM)

The cubic feet per minute (CFM) rating indicates the airflow capacity, a crucial consideration depending on the device's heat generation. High-CFM fans are necessary for larger, high-power devices, while low-CFM models are more appropriate for compact electronics.

2. Operating Temperature Range

Depending on the application, fans may be exposed to high temperatures. Ensure the fan’s temperature tolerance matches the operating environment, especially in automotive or industrial applications where heat levels can be extreme.

3. Noise Level (dBA)

For applications like medical devices and consumer electronics, fan noise can be a key concern. Lower dBA ratings signify quieter fans, essential in settings where noise reduction is critical.

4. Power Consumption

Selecting energy-efficient fans can contribute to lower operational costs and enhance overall system efficiency. Fans with brushless DC motors typically offer lower power consumption and extended lifespan.

Conclusion

Cooling fans are indispensable in the electronics industry, serving as a crucial component for temperature management and device longevity. Selecting the right fan model involves careful consideration of the manufacturer, parts, applications, and specific specifications like package, case, and noise levels. By understanding the requirements of different applications—from data centers to automotive electronics—procurement professionals and engineers can ensure optimal device performance and reliability.

With rapid technological advancements, it is essential to stay updated on the latest fan models and specifications. Cooling fans may appear to be a simple choice, but their role in safeguarding sensitive electronics is paramount, impacting everything from user experience to device lifespan. Choosing the correct cooling fan enhances efficiency, reliability, and safety across various industries, making it a vital decision for every professional in the electronics field.

For more information or to request a quote, please feel free to send us an RFQ.