Innovative Uses and Model Selections of CAN Transceivers in Modern Electronics

Designed primarily to manage data exchange within electronic control units (ECUs), CAN transceivers enable robust, error-free connections essential in high-stakes environments. This article dives into CAN transceiver manufacturers, top models, applications, and features that make these components a critical choice for engineers and procurement professionals.

Top CAN Transceiver Manufacturers

Texas Instruments (TI): A leader in analog IC and embedded processors, TI’s CAN transceivers, like the TCAN1042 and TCAN1051, are optimized for automotive use, providing robust electromagnetic compatibility and improved signal integrity.

NXP Semiconductors: Advanced safety and diagnostics features, such as the TJA1042 and TJA1051, commonly used in industrial automation systems.

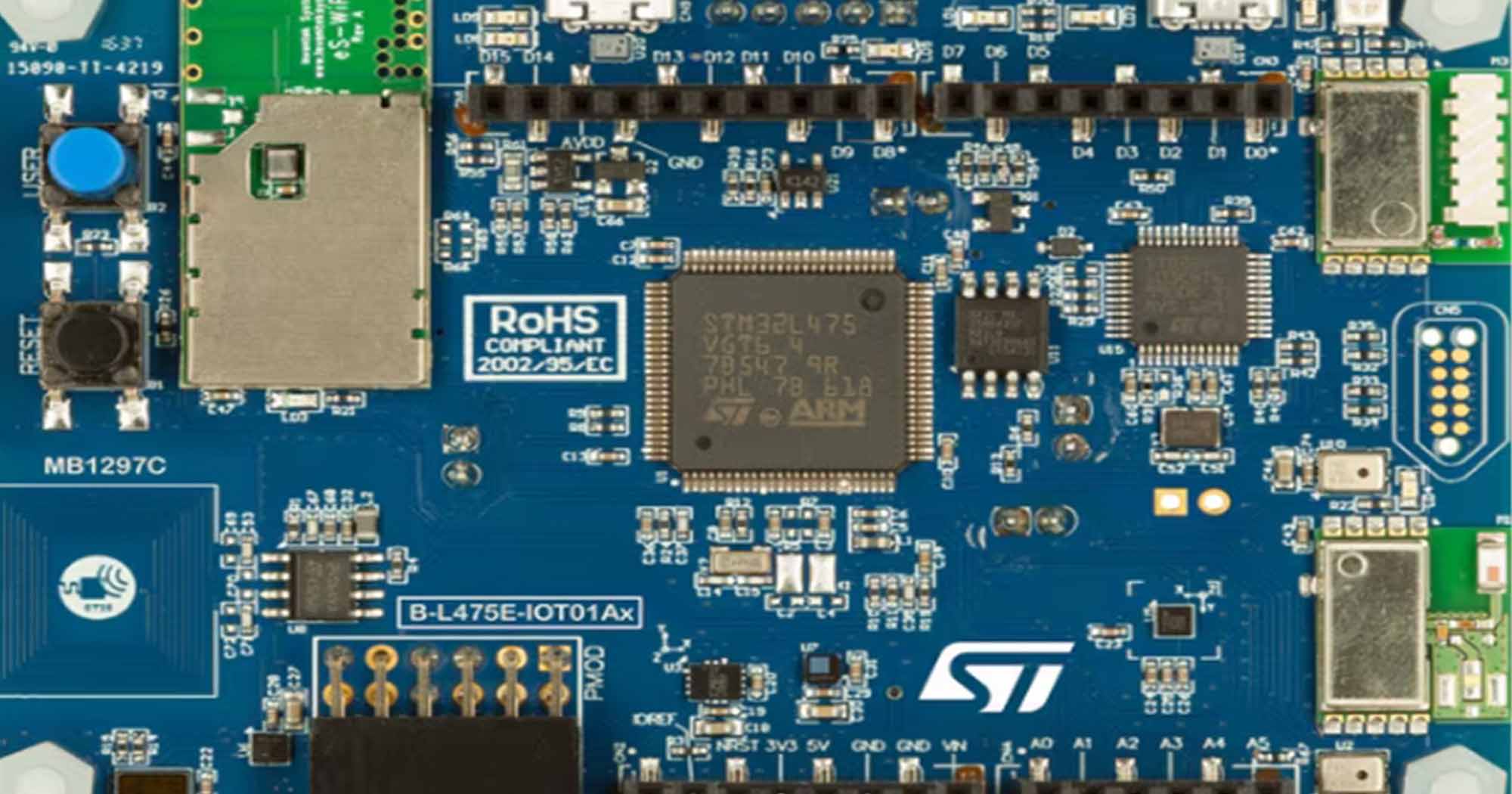

STMicroelectronics: Low-power designs, STMicro’s ISO11898-2 transceivers are highly reliable, providing fault tolerance and supporting applications with longer bus lengths.

CAN Transceiver Applications Across Different Industries

1. Automotive Systems

Automotive applications remain the largest market for CAN transceivers, where these components facilitate communication across ECUs managing engine control, transmission, braking systems, and infotainment. The durability and real-time data transfer capabilities of models like TI’s TCAN1042 make them ideal for automotive systems, which demand low latency and high fault tolerance. The ability to handle high data rates while minimizing interference is crucial, especially as vehicles integrate more sensors and intelligent control systems.

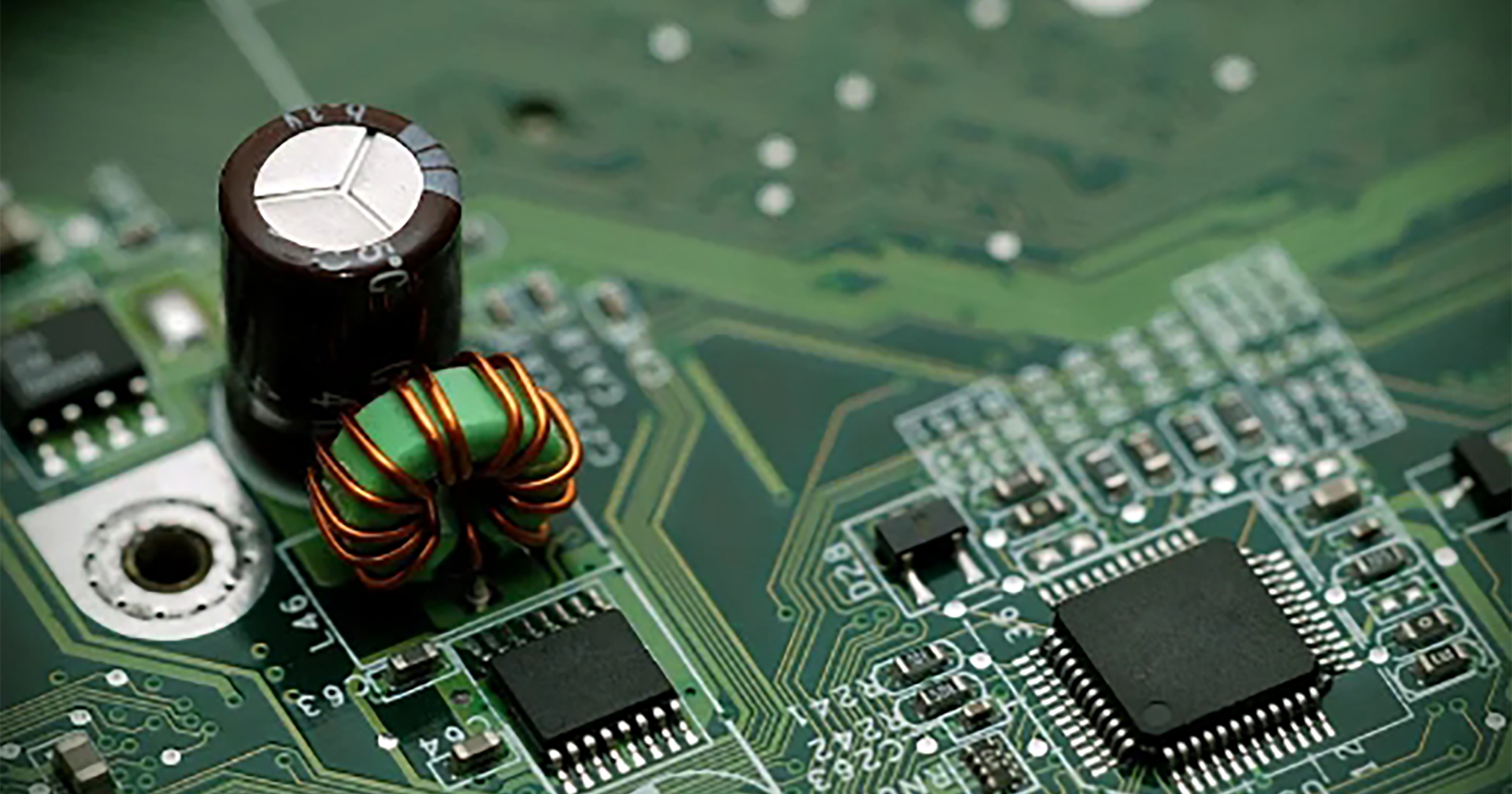

2. Industrial Automation

In industrial environments, CAN transceivers are essential in factory automation, robotics, and motor control, where they enable communication between machinery, sensors, and controllers. Industrial transceivers such as NXP’s TJA1051 provide reinforced EMC (Electromagnetic Compatibility) shielding and feature diagnostic capabilities, which allow engineers to monitor system health and preempt failures. This helps maintain continuous operation and improve safety in automated workflows. Additionally, their rugged design withstands electromagnetic disturbances common in manufacturing environments.

3. Medical Devices

Medical equipment increasingly relies on CAN transceivers to streamline communication between various electronic components. For instance, STMicro’s CAN transceivers, compatible with ISO11898-2, are commonly used in devices such as ventilators and patient monitoring systems, ensuring data integrity and uninterrupted performance in sensitive medical applications. Medical devices benefit from these transceivers’ low power consumption, which is essential for portable medical equipment requiring long battery life.

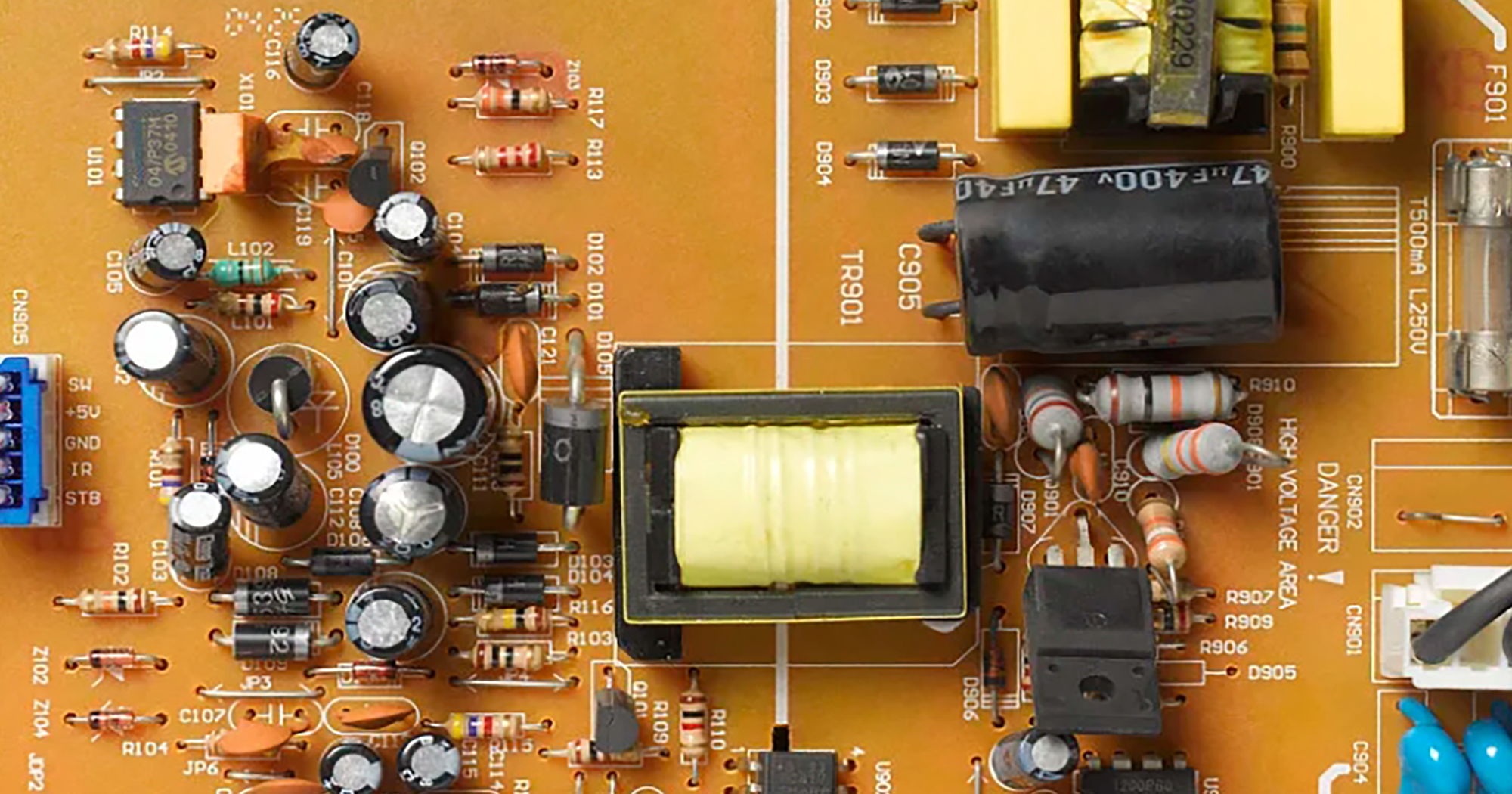

Package Types and Mounting Options for Optimal Integration

CAN transceivers come in multiple package options to fit a range of PCB designs and constraints. For example, Texas Instruments offers the TCAN1042 in industry-standard SOIC-8 and VSON-8 packages. These packages ensure flexibility, making it easier to fit CAN transceivers onto compact or complex circuit boards. The small package options are particularly advantageous in automotive and medical applications, where space is limited, and thermal management is essential.

1. SOIC (Small Outline Integrated Circuit)

The SOIC package is widely used due to its ease of installation and compatibility with various automated soldering methods. It provides a balance between durability and space efficiency, suitable for automotive applications where components must endure vibration and temperature fluctuations.

2. VSON (Very Small Outline No-lead)

For smaller devices or high-density circuits, the VSON package is an ideal choice. It offers thermal efficiency and reduces the overall footprint of the transceiver, which is useful in portable or space-constrained applications such as medical devices.

Key Features to Consider When Choosing a CAN Transceiver

When selecting a CAN transceiver, engineers and procurement specialists need to assess the following features to ensure compatibility and performance:

Data Rate Compatibility: High-speed CAN transceivers supporting up to 1 Mbps (e.g., NXP’s TJA1051) are ideal for applications requiring rapid data transfer, such as industrial automation and real-time automotive systems.

Electromagnetic Compatibility (EMC): CAN transceivers with robust EMC are critical in industrial and automotive environments where electronic interference is prevalent. Models with enhanced EMC, like TI’s TCAN1042, help maintain reliable communication in noisy conditions.

Fault Tolerance: For safety-critical applications, fault tolerance is essential. CAN transceivers with built-in diagnostic capabilities help detect errors and prevent complete system failures.

Low Power Consumption: In battery-powered applications, such as portable medical devices, low power consumption is vital to prolong battery life. The low-power modes offered by STMicro’s transceivers make them suitable for these applications.

Conclusion

In today’s interconnected electronics landscape, CAN transceivers are vital components for enabling efficient, reliable communication across various systems. They are especially prominent in automotive, industrial, and medical applications, where high data integrity and fault tolerance are crucial. By selecting CAN transceivers with the right features and packages for their applications, engineers and procurement professionals can enhance system stability, reduce downtime, and ensure lasting performance in demanding environments.

For more information or to request a quote, please feel free to send us an RFQ.